TB Sorter

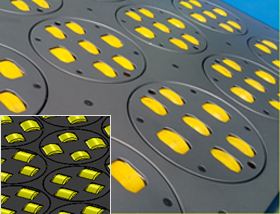

Product Figure

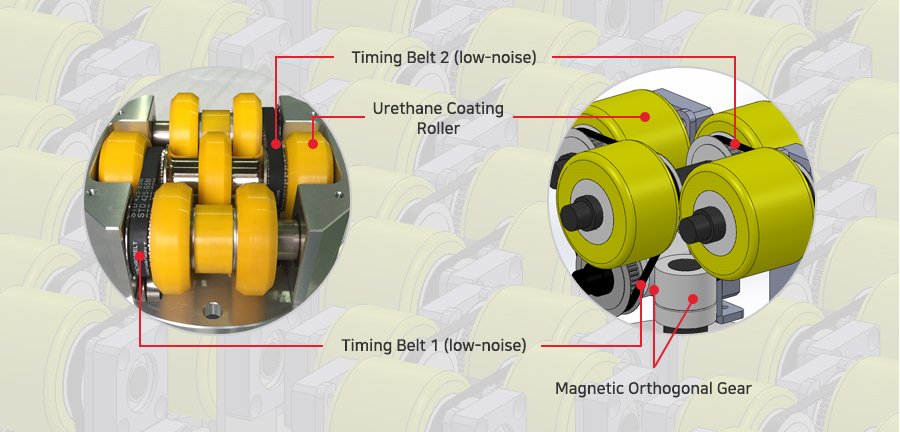

It excellently propels because its surface is coated with lots of urethane coating roller.

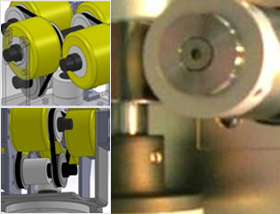

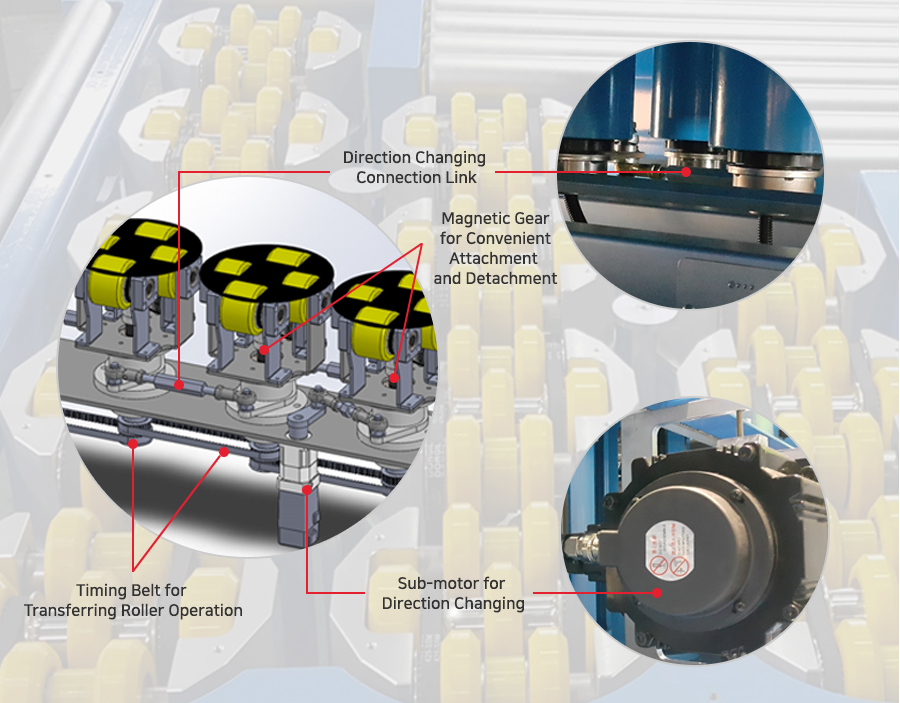

Since it uses a sub-motor, it changes direction quickly and accurately and can change direction by 45 degree.

It makes no noise because it separately operates with an equipped mag gear for each turning block.

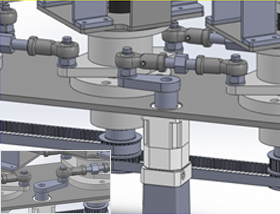

Because it uses timing belt for roller’s rotation, it lasts long and accurately operates.

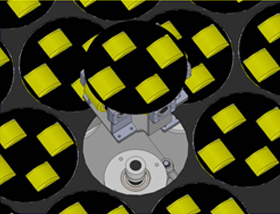

It is easy to replace when it malfunctions(bring blocks to the upper part and replace)

The upper plate is hard coated in for abrasion durability and friction minimization.

TB Structure

Structure of Direction Changing Device

Function and Specification

| Type | Large | Medium |

| Maximum Cargo | L1500 x W800 x H700 (50Kg) | L1500 x W800 x H700 (30Kg) |

| Minimum Cargo | L200 x W250 x H10 (50g) | L150 x W120 x H10 (50g) |

| Moving Velocity | 90 ~ 110 m/min | 90 ~ 110 m/min |

| Process Capability | 8000~10,000 per hour | 8000~10,000 per hour |

| Drive | Roller Rotating Motor (0.2Kw * 5 =1 Kw) Direction Changing Motor (0.2Kw * 5 = 1 Kw) |

Roller Rotating Motor (0.2Kw * 5 =1 Kw) Direction Changing Motor (0.2Kw * 5 = 1 Kw) |

| Size and Quantity of Roller | External Diameter 68mm * width 30mm – 7/block |

External Diameter 68mm * width 50mm 4/block |

| Temperature for Usage | 5~30 degrees | 5~30 degrees |

| Discharged Angle | 30~45 degrees | 30~45 degrees |

| Weight | 360 Kg (4 columns 5 row direction 3) | 360 Kg (4, 3 columns, 6 rows direction 3) |