Cross Belt Sorter

Cross Belt Sorter system composition and function introduction

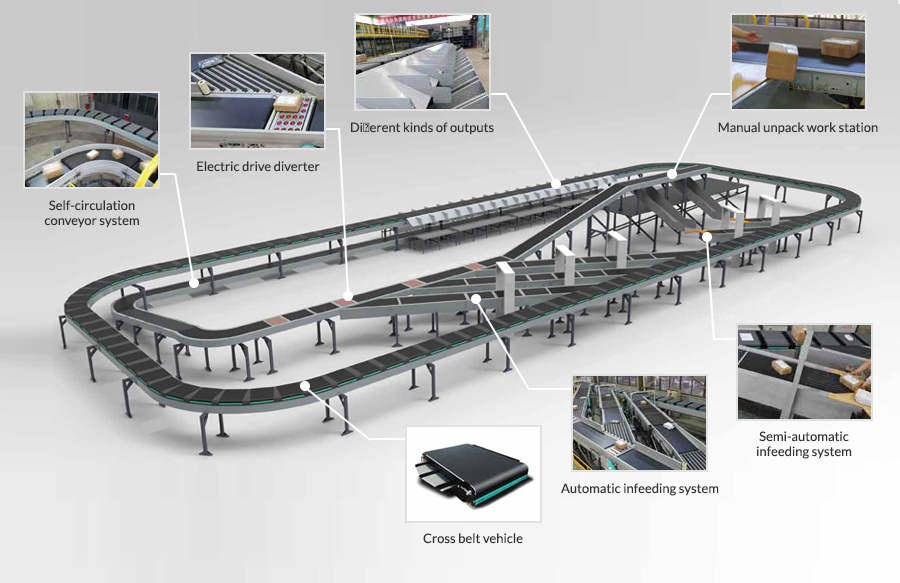

Cross belt sorter system is composed of infeeding part, sorter host, outfeeding part and control system. Items enter sorter hose by control system from infeeding system for sorting operation. Outfeeding system will help locate items physical location and storage to achieve its sorting function.

Infeeding system

To achieve high effciency and accurate operation of sorter host. Function of this system is to automatically measure physical parameter and information identification of items to be sorted, to make sure items are properly and synchronously infeed onto high speed running sorting vehicle.

Damon narrow belt sorter system is able to provide you with customized fully automated, semi-automated or manual operated infeeding system according to working environment.

Sorter host system

Sorter host is the main part to implement system sorting operation, with the function of delivering items with sorting information to the right sorting diverts in accordance with logical relation. Damon cross belt sorter system adopts servo direct drive technology, instant start in millisecondto ensure items keeping in the middle of vehicle during loading and unloading as well as reduces sorting error rate.

Outfeeding system

It is the end equipment in sorting system. It will temporarily store the items delivered by sorter host, at the same time, it will inspect and display related parameters of items and transmit these information to master control system and manage them. Different kinds of outputs can be used to match the wide range of items that can be handled. Items can be directly sorted into outputs such as chute, bag rack,roll cage etc based on patterns of items to be sorted.

Control system

Control system is the brain and nerve of the whole sorting system. It integrates mobile power supply technology, mobile communication technology,f ield bus, OPC communication, industrial Ethernet communication, PLC servo and frequency conversion technology etc. It not only coordinates each function module, the communication function in the control system also can exchange data and management policy with the upper management system, through this exchange makes the sorting system become an integral and close part of the whole logistics management system

Dare CBS-I main performance parameter

Cross belt sorter is featuring with high effciency, low consumption, high speed, low noise, high cost performance and low error rate. Its low consumption loop drive, cross belt servo drive and low noise loop running mechanism have already get to an international advanced level, equal to domestic leading level.

| Cart Pitch(mm) | 500/600/800 | Running Speed (Adjustable) | 2-2.4m/s | Product Size | ≤1000*600*600 | Noise Level | <70Db(A) |

|---|---|---|---|---|---|---|---|

| Turning Radius(mm) | 2880/3442/4080 | Sorting Error Rate | <0.0001 | Product Type | Soft pack/Tote/Carton | Equipment Monitoring | SCADA |

Test loop of cross belt sorter

Dare CBS-I product features

1. Energy Saving Circulating Technique (Straight Motor)

- High-performance Line

- Narrow wheels operate in both ways.

- High-heat Conducting Aluminum Heat-resistant Material

- High-density Heat Release and Resistance Technology

- Overall Modularization Technique

2. Crossbelt Sub-power Roller Straight Drive Technology

Obtain accurate array of items by replacing traditional synchronized drive through pulse measurement.

- Sun-power Roller Drive enables accurate incoming and outgoing items with various weights.

- It instantly drives once turned on and has a faster responding system and efficiency.

- Simple structure of device body, space saving, lightweight, energy saving structure, convenient maintenance, and installation.

3. High-speed, low-noise

Perfect combination with optimized body made of super light aluminum alloy and low-noise moving device, operating noise level is below 65db

4. Modularization Prompt Separation, Maintenance, and Management

Module structure and industrial design and fast speed Assembly and disassembly are introduced. Crossbelt cart can be replaced in less than 5 minutes. Convenient maintenance and management