Conveying & Sorting Series

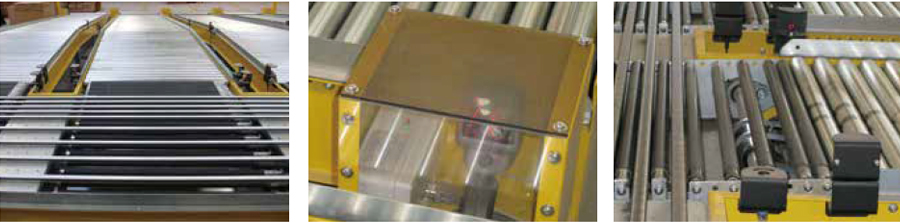

NBS-D30 narrow belt sorter was developed with the development of e-commerce. It is composed by a number of equally spaced narrow belts. Lifting roller or swivel wheel transfer mechanisms are embedded into the space between narrow belts. The transfer rollers or the swivel wheels are mounted lower than the narrow belt conveying surface.

When an object is required to be diverted, the transfer rollers or swivel wheels raise above the conveying surface driving the object perpendicular to the conveying direction. This device is very different from large sorting equipment and is more similar to general conveyor equipment. Features include a lightweight structure, simple maintenance, wide adaptability of sorting a variety of products, cost-effective and low noise at high speed. Its modular construction makes it easily expandable and adaptable to changes of the sorting spurs. It has been widely used in modern logistics distribution centers such as pharmaceutical distribution sorting, sorting of books and audio-visual products, sorting of flat express sachets, electronic sorting, sorting of clothing and groceries etc.

Product features:

D30-NB Narrow-belt Sorter

General specifications

| No | Item | Speci cation |

| 1 | Capacity | 40 p/min |

| 2 | Dimension of items | Min: 300*300, max: 700*700 |

| 3 | Weight of items | Max: 30kg per part |

| 4 | Main line speed | 40-75 m/min |

| 5 | Transfer speed | 50-80 m/min |

| 6 | Length | 25m |

| 7 | Width | 510mm (4 belts), 620mm (5 belts), 730mm (6 belts), 840mm (7 belts) |

D30-SW Swivel Wheel Sorter

The main line of D30-SW swivel wheel sorter is belt conveyor or roller conveyor. There are two sorting types for swivel wheel sorting devices. The first is separate embedding sorting and the second is online bidirectional sorting. Drive and driven are used for power drive. Options include pneumatic or electromagnetic actuation for the swivel wheel drive. Features of this design is to track conveyed goods accurately and stably. Set sorting positions may be conveniently located at any position along both sides of the conveyor line to satisfy customers with different sorting requirements. Achieves both maximum sorting rates and best economic efficiency.

Product features:

High sorting capacity

Swivel wheel device is designed for high speed and bidirectional sorting operation to both sides at the same time. Maximum rate can be 4200 pieces/hour.

Energy saving and environmental protection

Utilizes light weight material with low energy consumption structure as well as low power and source power (conveyor) drive to achieve successful operation.

Multiple modes and applications

Swivel wheel device uses unique online bidirectional sorting technology and is self-powered or conveyor source powered for its drive. Drive for the swivel wheels can be pneumatic or electromagnetic dependent on the availability of air supply at the customer’s site. These all ensure the product is economical and practical.

Flexible and stable sorting

Online double-row swivel wheel technology protects conveyed goods from vibration and damage. Stable and flexible sortation of goods from light duty to heavy duty range of maximum 35kg.

Low noise

Utilizes new materials and noise elimination technology which make the environment more comfortable (electromagnetic steering type).

Easy layout and maintenance

Uses modular unit design and embedding combination structure, easy for sorting positions to be placed at any position along both sides of the conveyor line. Product is practical, simple, convenient and easily maintained.

General specifications

| No | Item | Speci cation |

| 1 | Sorter type | Online swivel wheel |

| 2 | Sorting capacity (part/h) | Max: 4,200 parts/h |

| 3 | Max conveying speed (m/min) | 90 m/min |

| 4 | E ective width (mm) | 517, 617, 717, 817 |

| 5 | Number of divert | Depends on length of conveyor and dimension of goods to be sorted |

| 6 | Sorting direction | Single side sorting and dual sided sorting |

| 7 | Conveyor type | belt conveyor, roller conveyor |

| 8 | Dimension of item (mm) | 250-700 (L); 180-600 (W); 30-500 (H) |

| 9 | Weight (kg) | 0.5-30kg |

CSi is a professional intelligent material handling solution supplier in Holland. The Powerball sorter well known for its hi-tech performance and reliable 24/7 non-stop running.

The Cooperation between Damon and CSi started from 2010 and signed a strategic cooperation agreement in 2013.Based on the high efficiency Powerball sorter of CSi, Damon and CSi have developed the Powerball sorter together.

Applicable industries:

Foods, drink, tobacco, E-commerce, light industry, warehouse logistics and other automation industries.

Application environment:

Unique High-speed Sorting Equipment-Powerball

- Suitable for items packaged in different shapes and dimensions.

- Can be used in goods diverting, merging, position adjustment, turning

- No twisted belt because of tapered roller drive

- Round powerball handles items gently without damage.

- Easy and quick to replace due to embedded module design

- Use high-quality European drive motor, gearbox and starter

- CE certified, high stability, extremely low maintenance cost

- Has been applied in a well-known E-commerce project in China.

- Key specifications of the product:

- Suitable for goods in size: min: 100*100mm, max: 600*400mm.

- Suitable for single piece in weight: less than 35kg.

- Rate: 5,000 p/h

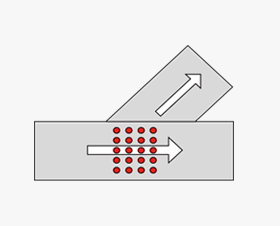

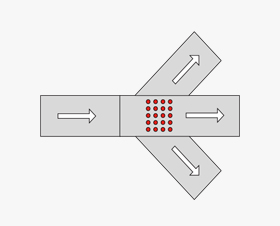

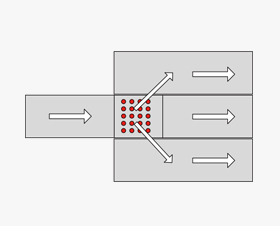

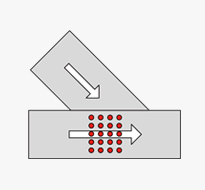

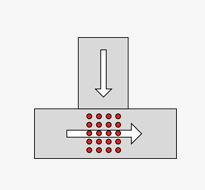

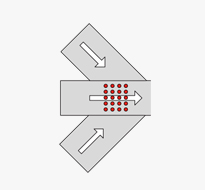

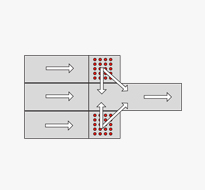

Function diagrams:

Divert

45°left sorting in single direction

45°Bi-directional sorting

45°Bi-directional parallelly sorting

Merge

45° left merging in single direction

90°Merge

45°Bi-directional merging

45°/ 90° Bi-directional parallel merging

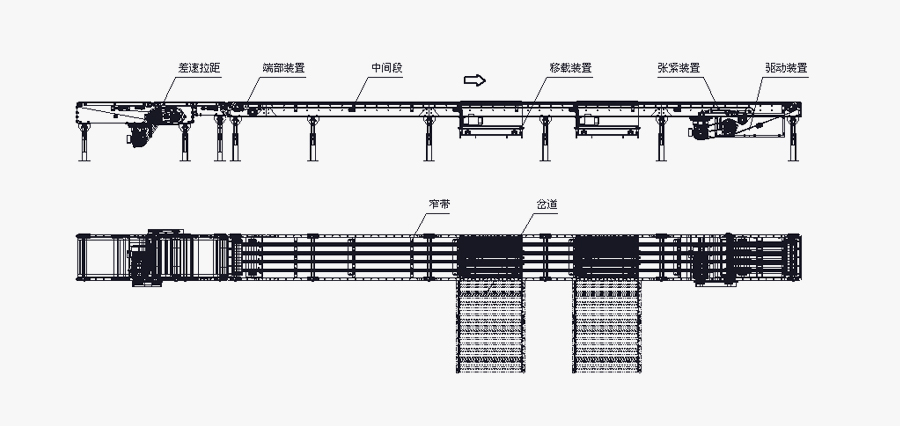

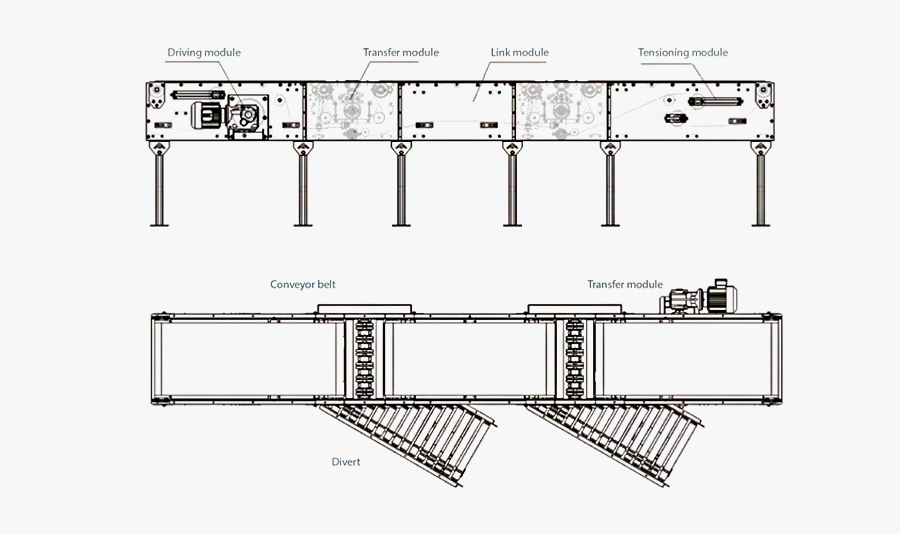

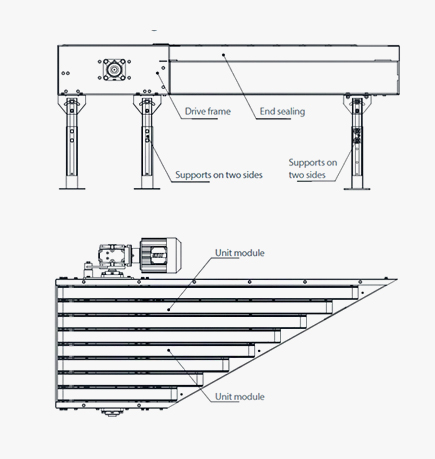

The narrow belt merge conveyor is widely applied in conveyor and sortation systems. Damon’s new MB-D1002 narrow belt merge conveyor is modular in design. Fixed side by side on the frame with several standard series unit module in a corresponding sequence.

One drive roller drives the narrow belt in all unit modules. A unique tensioning and offset device is used to meet requirements for narrow belt tensioning and offset in each unit module. It provides high cost performance thanks to its new mechanical structure to improve comprehensive performance and life cycle.

Fast assembling and disassembling, simple maintenance

The new narrow belt merge conveyor uses a modular structure. Unit modules and frames are installed separately. When disassembling and repairing, there is no need to disassemble each unit module and frame. You only need to disassemble the unit which needs to be repaired. This makes assembling, disassembling and maintenance much easier and improves their efficiency.

Standard product, low cost

The new narrow belt merge conveyor uses a modular unit structure from standardized parts which reduce product lead time as well as reducing the maintenance costs.

High speed, low noise

Maximum speed of the new narrow belt merge conveyor can be 120m/min which can meet needs of high efficiency conveying and sorting. Unit module rollers are constructed from a new plastic material which reduce noise when it is running.

Unique tension & offset

The new narrow belt merge conveyor adopts a unique tensioning and offset device for narrow belts of different lengths to improve the life cycle of parts.

Stable and reliable conveying

The new narrow belt merge conveyor can convey smaller products by reducing the gap between the narrow belts. At the same time, the unit module joints ensure a stable and reliable conveying operation.

Simple look, easy to use

The new narrow belt merge conveyor uses a fully enclosed structure with a simple look. As the narrow belt merge is a free standing unit, when used with other equipment, there is no need for connecting braces or brackets which provides easy installation and maintenance.

MB-D1002 Narrow-belt Merge Conveyor

Structure

Example

General specifications

| No | Item | Speci cation |

| 1 | Conveyor type | Roller drive, narrow belt conveying |

| 2 | Merge rate (pcs/h) | 1,800~5,500 (L=500) |

| 3 | Conveying speed (m/min) | 30~120 |

| 4 | E ective width (mm) | 574, 655, 736, 817, 979 |

| 5 | Merge angle | 30°, 45° |

| 6 | Merge direction | Left, right |

| 7 | Type of conveyed goods | Carton, tote, package |

| 8 | Dimension of conveyed goods | 200-1,350(L), 100-900 (W), 30-600 (H) |

| 9 | Load capacity (kg) | 50kg (Max) |

Application of narrow-belt merge conveyor

Narrow belt merge conveyor is usually used in courier, logistic, warehouse, food and pharmaceutical industry.