Robot & Handling

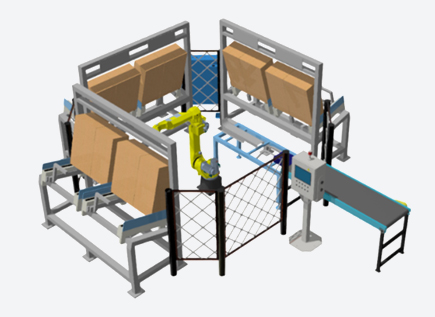

ROBOT PALLETIZING SYSTEMS

High speed palletizing with a various payload, multi pick and place, customized solutions. We are specially designed for demanding palletizing tasks and then, shot cycle time, increased throughput, low space requirements and cost-reductions.

Variable gripper

- Vacuum gripper

- Pneumatic claw gripper

- Vacuum gripper with pallet clamp

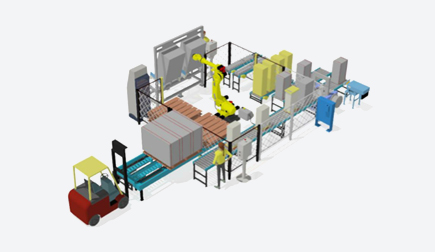

ROBOT DEPALLETIZING SYSTEMS

3D Vision depalletizing robots are designed for depalletiziation of multi-SKU, single SKU and random pallet of cartons. This system is a optimized logistic solutions that provide a full systems for AS/RS, inbound of distribution centers and picking area.

- 3D Vision & laser measuring units.

- Vacuum gripper

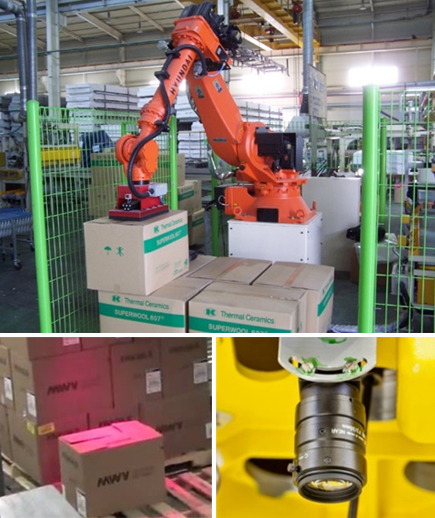

ROBOT HANDLING SYSTEMS

Robot handling systems will automate your production lines for low cost, high reliability and shot cycle time with wide variety of components.

All systems with manipulator have a robot hanger for handling and manufacturing the product, a camera system and control system and robot controller.

Applications

- Assembly

- Parts handling

- Vision inspection

- Press handling

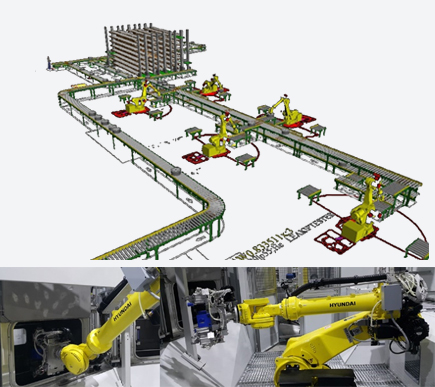

RANDOM CASE ERECTOR

Random case erector is six-axis robot with multiple case magazine and a bottom flap folder with integrated tape head. The robot has a flexible end of hanger to pick and erect multiple case, eliminating the need for multiple erectors, the floor space they consume and costly changeover downtime. Six case magazines with accommodating six different case size.

- Six axis robot and controller

- Robot hanger with vacuum and dropped case detection.

- Dual gravity case magazines.