Storage, AGV & EMS

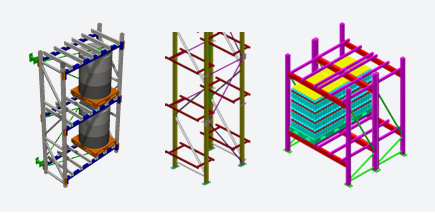

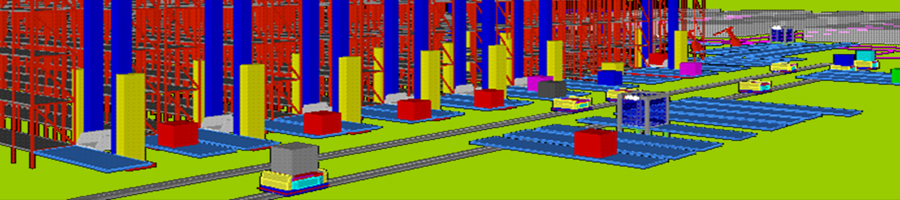

HIGHBAY STORAGE SYSTEMS(AS/RS)

Variable design

- Installation height up to 50m

- Payload up to 30 tons

- Load width up to 6m long.

- Temperature range -25°C to 60°C

High performance stacker crane

- Up to 160 m/min travelling speed

- Up to 60 m/min hoisting & forking speed

- Inverted speed control

- Optical data communication device

- High accuracy positioning to encode

- and/or laser measurement

- Design by 3D Modeling & dynamic analysis

Safety device

- Motion over-time check for Travelling,

- hoisting and telescopic forking

- Mechanical stopper for travel and hoist

- Governor with wire tension

- Oversize check for carriage

- Telescopic fork interlock detect to travel

- Incorrect count check

- Power off for travel & hoist limited

High bay storage racks

- Loaded beam type

- Load arm type

- Double deep type

Advantage for Highbay storage system

- Up to a 70% space savings

- Up to 30% in the reduction of handling equipment, handling operators

- Up to a 40% reduction in stock costs

WMS

Warehouse Management System

WMS is an information management software whose purpose is to optimize the physical management and tracking of the flow of goods, from entry into the warehouse to dispatch, guaranteeing traceability.

- Dual server operation for redundancy

- Customizable architecture

- Multi-user, Multi-warehouse and multilingual functions

UNIT LOAD & MINI-LOAD STORAGE SYSTEMS

Unit load storage system

- Installation height less then 20m at the warehouse

- Payload up to 2 tons with pallet

Mini-load storage systems

- Load units Plastic box and totes, carton box, small steel pallets and others

- Payload up to 300kg

- Up to 240 m/min travelling speed

- Up to 120 m/min hoisting speed

- Up to 60 m/min telescopic fork

- Picking and replenishment positions

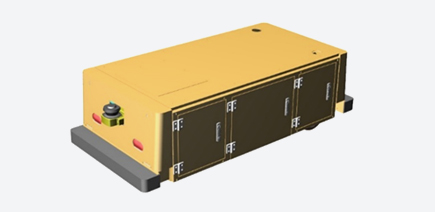

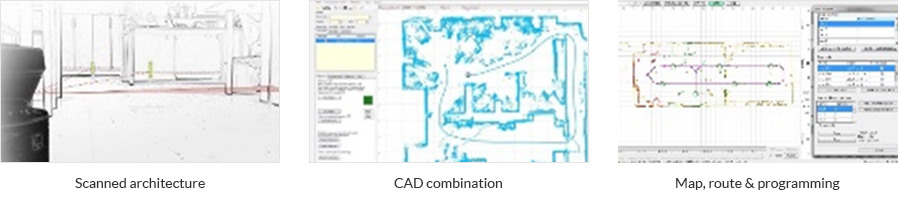

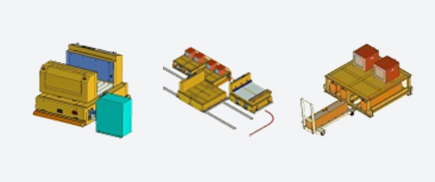

AUTOMATIC GUIDED VEHICLES(AGV)

AGV is a vehicle equipped with automatic guidance equipment, either electromagnetic or optical. Such a vehicle is capable of following prescribed guide paths and may be equipped for vehicle programming and stop selection, blocking, and any special functions required by the system.

Advantages

- Dynamic design solution and modular elements.

- Safe and predictable technology.

- Elimination of conveyor walls

- Re-usable asset and reduced labor costs.

- Electronic tracking of material and efficient scheduling.

- Adaptable to future changes.

AGV Guidance systems

- Inductive guidance

- Magnetic tape, spot guidance

- Laser navigation

- Vision based navigation

Loading type

- Chain & roller conveyor

- Telescopic fork at side

- Up/down at bottom

- Fork-lift type

Battery swap and charging

- Automatic charging

- Automatic swap

- Manual swap

Lithium-ion polymer Battery

- High energy density

- Long cycle life

- Quick charging

ELECTRIC MONORAIL SYSTEM(EMS)

Electric Monorail System(EMS) is designed using a single aluminum extruded section which makes the system clean and quiet, and flexibility as-well. Each carrier has its own drive unit and can run at variable speeds. The carriers can travel at speeds up to 120 m/min and operates with high stopping accuracy. Carriers can also be equipped with hoist and any other drop-lift for accurate vertical movements at any work station. Carrier can be changed monorail with track switch for horizontal movements.

RAIL GUIDED VEHICLE(RGV)

RGV is a flexible transportation vehicle. It can link multiple destinations and be a good and economic alternative of conveyor by its characteristic that is eliminate complex and fixed layout of conveyors, which enable simple and easy maintainable transportation system.

CONVEYOR SYSTEMS FOR PALLET

Pallet conveyors are used for routing, accumulation, elevating, and sorting large unit loads. Specific types of these unit load handling conveyors include: